As an addition to the sewing table of my wife, i built this geometric desk lamp out of wood/brass.

The entire lamp is built out of 18mm solid beech with brass hardware. Six polygons that are rotated 5° to each other are glued together to form the lamp shade.

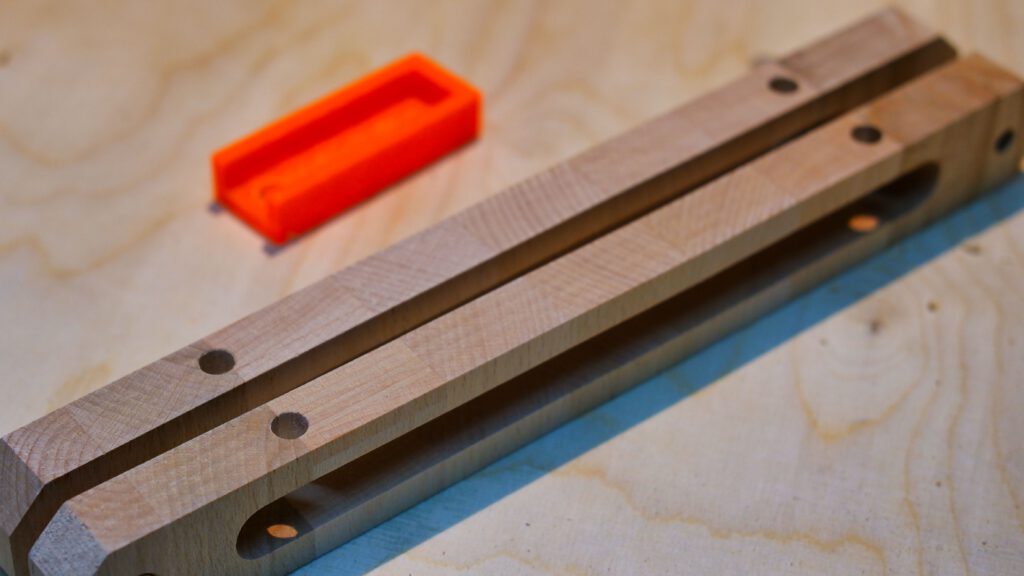

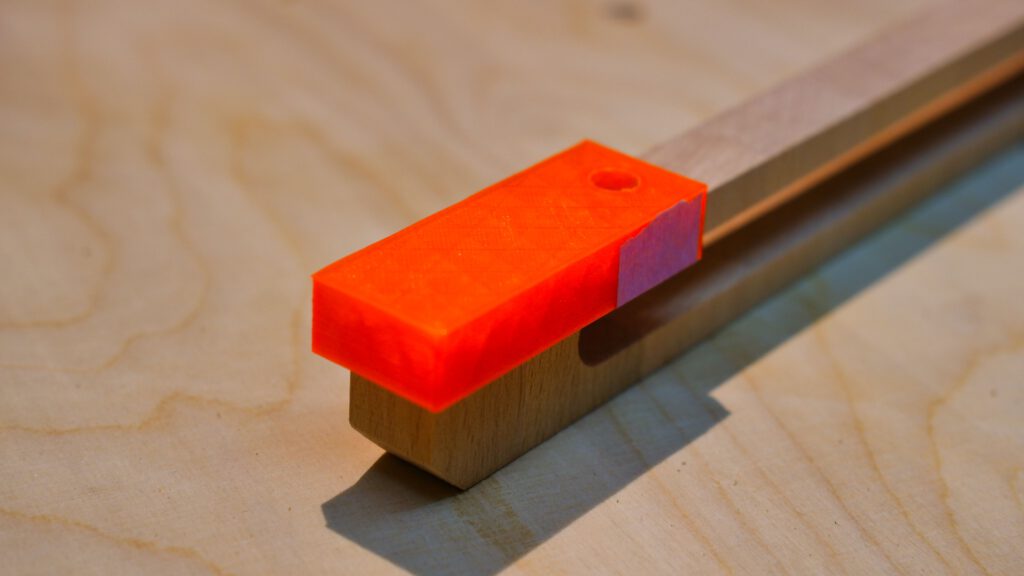

To make the assembly process of these complicated geometric shapes easier i build various 3D-printed assembly helpers. You can check them out below. Enjoy!

project facts

| dimensions: | ca. 560mm x 200mm x 400mm (HxWxD) |

| material: | 18mm solid beech, brass (thumb screws and lamp socket) |

| estimated material cost: | ~38,5€ |

| tools: | cnc-router, 3D-printer (optional), sander, drill press (or atleast a drill), electrical equipment to connect the lamp socket |

| difficulty: | medium |

| assembly time: | 2-4 hours |

| cutting time: | ca. 1 1/2 hour |

| printing time: | ca. 8 hours |

3D-model

materials

| material | estimated cost |

|---|---|

| 800x400x18mm solid beech | 5€ |

| filament for 3D-printed parts | 2€ |

| brass lamp socket E27 | 6€ |

| 3x brass thumb screw M6x25mm DIN464 | 13,5€ |

| 3m fabric covered cable | 10€ |

| 3x Threaded inserts M6x15mm | 1€ |

| sum | ~38,5€ |

assembly process

- Cut out all the wooden parts and the one brass part

- Print all the assembly helpers (optional but recommended)

- Glue the “arm-mount” to the base station

- Drill holes for the cabling using the drill guide

- Glue all the parts of the lamp shade together using the 3D-printed 5° fixture

- Glue the brass plate into the lamp shade

- Screw in the lamp socket and into the brass plate

- Screw all the pieces together using the thumb screws

- Route all the cabling through the arms

- Connect the cable to the socket and install a plug

Here is a video of the 3D-printed helpers in action:

Musiker: Fullstack

URL: https://icons8.com/music/

project pictures

social

If you want to stay tuned for future projects follow me on Instagram:

@things_ex_machina